Optimizing CNC Manufacturing with Cutting-Edge Techniques

Computer Numerical Control (CNC) manufacturing continues to evolve with advancements in automation, multi-axis machining, and AI-driven precision. Understanding these techniques enhances efficiency and accuracy across industries such as aerospace, automotive, and medical device production.

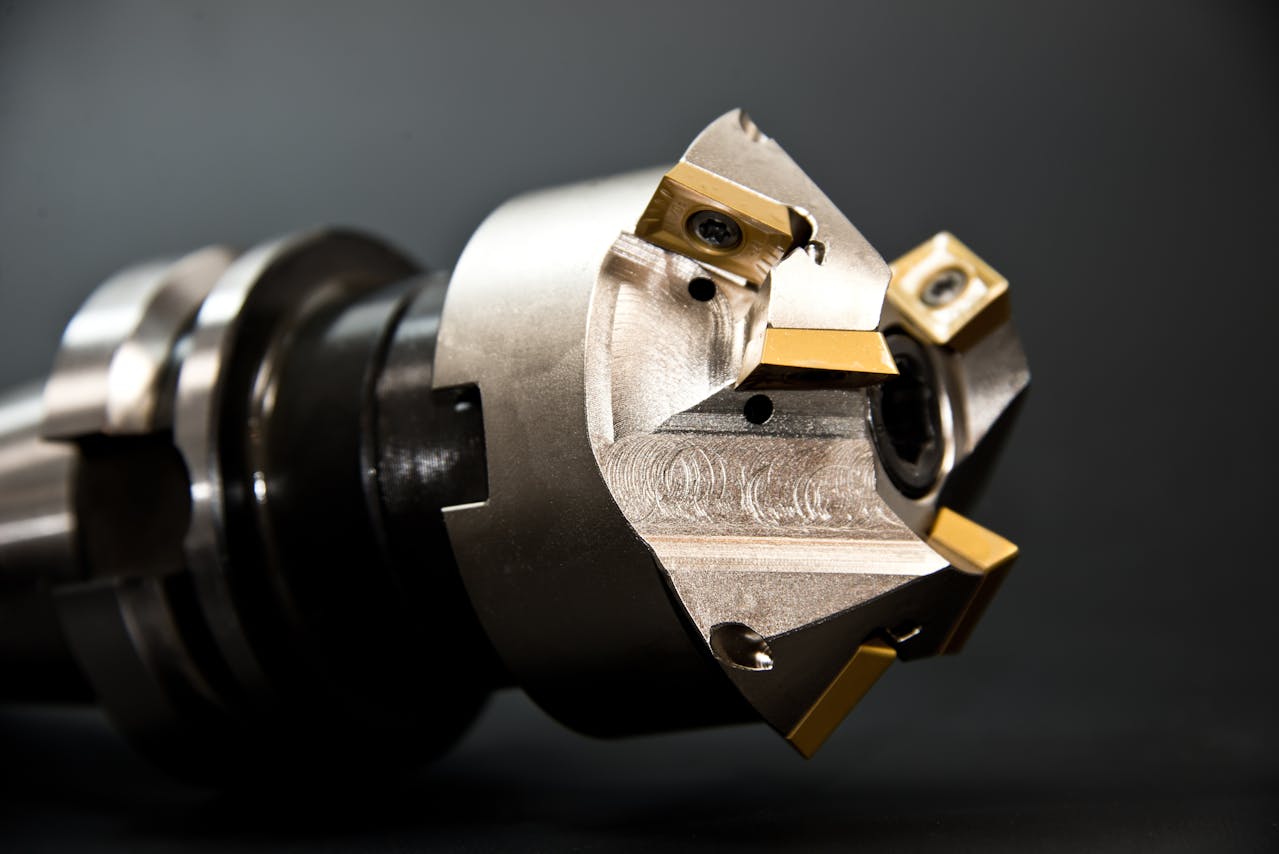

Improve CNC machining accuracy by integrating adaptive toolpath optimization, ensuring smoother and more precise cuts across complex materials.

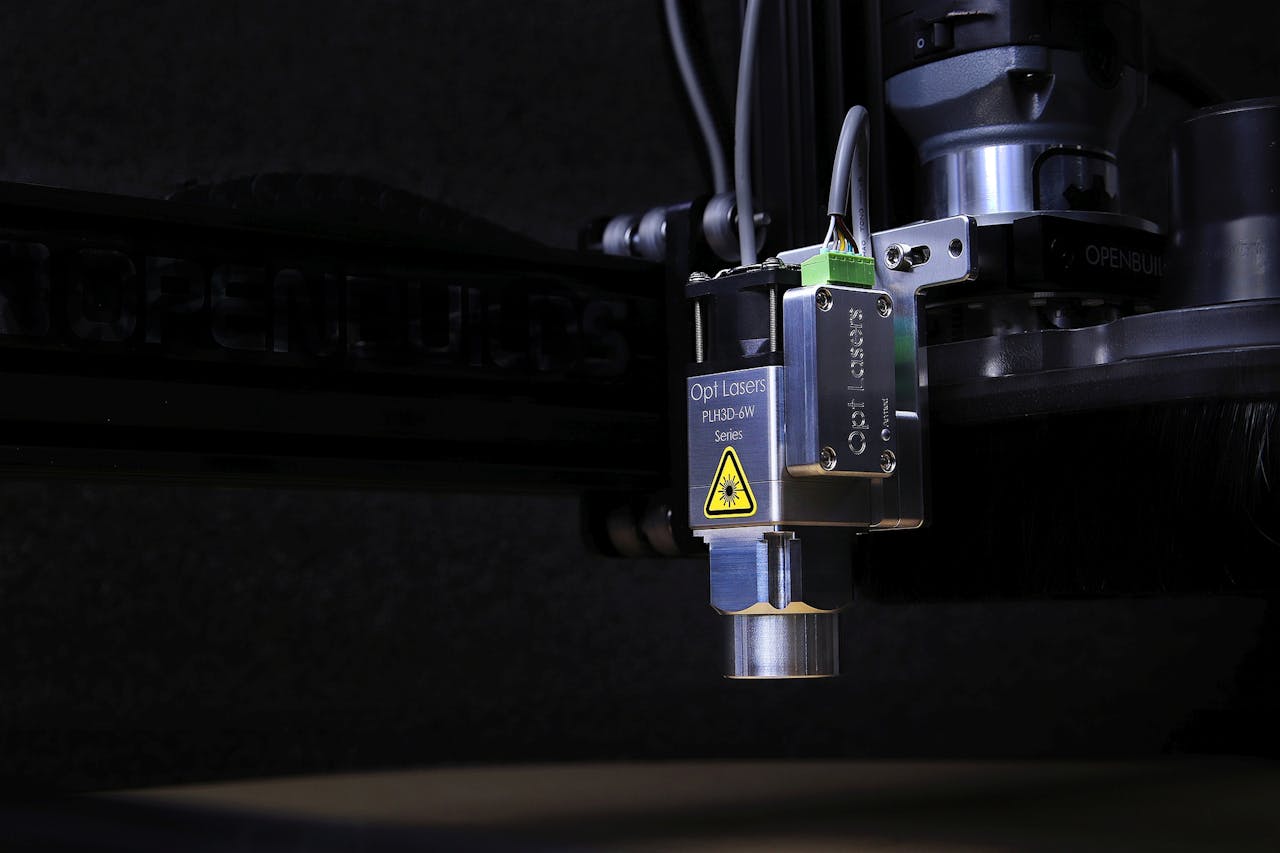

Leverage cloud-based CNC processing to enable real-time monitoring and remote operation, reducing downtime and enhancing workflow automation.

Optimize CNC programming with AI-assisted tool selection, automated error detection, and predictive analytics to streamline production and minimize waste.

Stay ahead in CNC innovation by adopting high-speed machining, hybrid manufacturing techniques, and smart sensors that refine manufacturing efficiency and reliability.